Sticky Postings

All 242 fabric | rblg updated tags | #fabric|ch #wandering #reading

By fabric | ch

-----

As we continue to lack a decent search engine on this blog and as we don't use a "tag cloud" ... This post could help navigate through the updated content on | rblg (as of 09.2023), via all its tags!

FIND BELOW ALL THE TAGS THAT CAN BE USED TO NAVIGATE IN THE CONTENTS OF | RBLG BLOG:

(to be seen just below if you're navigating on the blog's html pages or here for rss readers)

--

Note that we had to hit the "pause" button on our reblogging activities a while ago (mainly because we ran out of time, but also because we received complaints from a major image stock company about some images that were displayed on | rblg, an activity that we felt was still "fair use" - we've never made any money or advertised on this site).

Nevertheless, we continue to publish from time to time information on the activities of fabric | ch, or content directly related to its work (documentation).

Tuesday, June 14. 2016

Breatheable Food | #air #food #particles

Note: the architecture (of atmospheres) could become atomized into fine particles that aggregate in different manners along time, following different "rules" (these "rules" being the ones to be designed by the architect).

While we digg into sensors than monitor elements of the atmosphere (physical and non physical elements), we're definitely looking for a kind of architecture that would "deal" with these elements/particles and recompose them.

Via Cabinet (Spring 2001)

-----

By David Gissen

In the history of architecture and design there have only been a few "effects"—electric light, forced air—that have had the capacity to cause massive environmental and behavioral shifts. Last year at Barcelona's annual design fair, the Catalonian designer Marti Guixe presented another—breathable food. "Pharma-food, a system of nourishment by breathing," is an appliance that was developed by Guixe to explore the transformation of food into pure information.

Dust Food Muesli. Photos: Inga Knölke.

Pharma-food joins the work of other, primarily European, designers who are exploring alternative regimens for such activities as washing or eating. One of Guixe's Catalonian contemporaries, Ana Mir, is exploring a technology that allows one to wash without water. Like Guixe's approach, this project would allow washing to occur anywhere. In their work, these designers not only free regimens from their fixed location in relation to certain products; they also free these activities from their traditional engagement with the body. Unlike designers such as Philippe Starck or Richard Sapper, who strive to revise traditional technologies, Guixe has discovered that the problem of eating does not involve the design of a new type of stove, sink, or refrigerator—the problem of eating requires finding a new mouth.

Pharma-BAR. Photo: Inga Knölke.

Guixe, who has been studying alternative forms of eating for several years, realized that the breathing of "food" already occurs via the inhalation of dust that hangs in the air at work and at home. Guixe hypothesized that this form of eating, from which one gains a miniscule amount of minerals and vitamins, could be trans-formed into a more potent meal, a "dust-muesli," that would supply a powerful dose of nutrients. The Pharma-Food appliance, which sprays this ærosolized nutrition, connects to a computer and requires Microsoft Excel to enter exact values for such things as riboflavin, vitamin C, and protein. The combination of these nutrients are saved on the computer as documents with names such as "SPAMT," which has the nutrient "language" of tomatoes and bread, and "Costa Brova," a "seafood" dish that is heavy on the iodine and light on carbohydrates. Guixe imagines diners composing these "meals" and sending them as e-mail attachments to other owners of the Pharma-food emitter. "Like MP3," says Guixe.

While Guixe has explored the experience of eating this information, less explored and of equal significance is where this type of eating can now take place. Guixe imagines Pharma-food in a special "Pharma-bar," essentially a simple room with tables and chairs and several emitters. But why is this necessary when he has liberated food from kitchens and from forms of ingestion that require utensils and dishes? Pharma-food will allow eating to occur anywhere at any time; on subways, in cars, in our beds, while exercising, sleeping, or making love. Most interesting is what effect this device will have on the home, particularly the American home, which is dominated by the kitchen. While technologies are given free range at work and in other public spheres, the home is typically the place where devices such as Pharma-food are tamed and held in balance by a previous technology that the new device is meant to replace. Central heat did not eliminate the fireplace; it allowed this formerly grimy, soot-filled artifact to become an æsthetic symbol and heart of the American home. People began using fireplaces less, but when they did, they burned wood in them again instead of coal. Similarly, cooking the monthly meal may involve stoking a wood-fueled, cast-iron stove while simultaneously breathing a few appetizers with friends.

-

David Gissen is associate curator for architecture and design at the National Building Museum in Washington, D.C. He is currently developing an exhibition on human conveyance (elevators, escalators and moving sidewalks) and one on flying buildings.

Related Links:

Friday, July 18. 2014

Data Cuisine, food as data expression | #data #food

Via WMMNA

-----

Eat Your 3D Prints | #food #print

Via Make

-----

The first time someone lays a 3D-printed piece of candy in your hand, you almost feel bad about eating it. The virtuosity of these pieces confuses the senses: stunning hexagonal structures cluster together like a complex chemical construction, full-color starburst patterns curve as if made from fabric, and neon geometrical shapes interlock without a single seam. On first glance, you think each one is a piece of art and meant to be consumed only by the eyes. But then you taste it and realize this is a whole new recipe.

Sugar 3D printing is a relatively new development and a fun sense-oriented detour under the “additive manufacturing” umbrella, which has often been largely about function. Not to mention this is a huge development in 3D printing materials alone, especially considering that they’re all edible. No chemicals allowed. If we can 3D print with sugar, you have to wonder how many more materials are out there that we haven’t even considered yet.

Most importantly, food 3D printing empowers us to build upon the culinary traditions that are so deeply imprinted on our cultural psyche. Food, as we can all attest, occupies a prominent space in the human experience. After all, we always seem to gravitate toward the kitchen as a gathering place, and one of the greatest pleasures of being human is making and enjoying a meal with someone else, whether it’s to catch up, celebrate, remember, or imagine the future. As culinary practices shift, so too do the experiences that surround them: they become heightened, enriched. This is exactly the kind of progression that food 3D printing will catalyze, as bakers, chefs, and confectioners take hold of capabilities never before realized, giving new shape to the moments of life that revolve around our food culture.

The Sugar Lab

The Sugar Lab at 3D Systems is the birthplace of sugar 3D printing. Think of it as our bakery and the place where all the amazing, sweet creations you see here come to life. Liz and Kyle von Hasseln, who began developing 3D printed food out of their small apartment while they were architecture graduate students, founded the Sugar Lab. For this husband-and-wife team, it started as a simple experiment with unusual 3D printing materials. They first attempted to print in wood, using sawdust, and later ceramics and concrete. Those all produced mixed results. But next, motivated by the need for a special birthday decoration, they tried sugar. After a few months spent perfecting the recipe, they realized they were onto something. A bit later, The Sugar Lab took form as a full-fledged business, with Kyle and Liz using a 3D Systems 3D printer that they’d retrofitted to be food safe.

ChefJet

Now as part of the 3D Systems family, their amazing invention has taken the next step with the introduction of the ChefJet 3D printer, the first sugar 3D printer available for restaurants, bakeries, catering companies, and more. We first revealed the ChefJet at International CES 2014, and the excitement has rightfully been through the roof. Since then, candy giant Hershey’s has joined our efforts to find delectable and captivating new ways to print candy.

As Kyle and Liz put it at CES, the ChefJet presents a fantastic new outlet for 3D printing to spread throughout mainstream culture. Food being such an integral part of our social interactions, our family gatherings, and our time at home, these edibles have the chance to open a lot of eyes to the personal power of 3D printing and its myriad uses.

How It Works

For those familiar with the different methods of 3D printing, sugar 3D printing is similar in principal to other technologies like ColorJet or Selective Laser Sintering (SLS). It uses a bed of powdered materials (in this case sugar), flavoring, and sometimes cocoa powder. A stream of water bonds the sugar together within the material bed to form a single layer, then the build platform lowers, a new layer of sugar is spread over the build area, and the machine builds the next layer. So it goes layer by layer until the sculpture is finished.

The results, as you can see here, are just as magnificent as printing with plastic or metal. The ChefJet is virtually unlimited by the geometry or the complexity of the model you want to print. You can create interlocking pieces, perfectly straight lines, and smooth curves, all in full color if you desire. Considering the sugar sculptures that it creates, it makes sense that architects thought it up.

To date, The Sugar Lab and the ChefJet have created everything from customized sugar cubes and structural cake decorations to premium cocktail decorations and exact scale Ford Mustang replicas. Flavor choices are equally delicious with mint, cherry, sour apple, milk chocolate, and others.

But what I love about the ChefJet and other 3D printers is that they provide yet another tool and a multitude of other options when it comes to artistic applications. I discussed this in last month’s blog: 3D printing in this respect can supplement the traditional methods, and recipes, that we’ve developed over years and years. In this case, it’s about building on tradition, not overpowering or replacing it. So now bakers and confectioners can match their delectable flavors with never-before-seen visual aesthetics. They can have their cake and eat it too.

Related Links:

Wednesday, June 26. 2013

The audacious plan to end hunger with 3-D printed food

Via Computed·Blg via Quartz

-----

Anjan Contractor’s 3D food printer might evoke visions of the “replicator” popularized in Star Trek, from which Captain Picard was constantly interrupting himself to order tea. And indeed Contractor’s company, Systems & Materials Research Corporation, just got a six month, $125,000 grant from NASA to create a prototype of his universal food synthesizer.

But Contractor, a mechanical engineer with a background in 3D printing, envisions a much more mundane—and ultimately more important—use for the technology. He sees a day when every kitchen has a 3D printer, and the earth’s 12 billion people feed themselves customized, nutritionally-appropriate meals synthesized one layer at a time, from cartridges of powder and oils they buy at the corner grocery store. Contractor’s vision would mean the end of food waste, because the powder his system will use is shelf-stable for up to 30 years, so that each cartridge, whether it contains sugars, complex carbohydrates, protein or some other basic building block, would be fully exhausted before being returned to the store.

Ubiquitous food synthesizers would also create new ways of producing the basic calories on which we all rely. Since a powder is a powder, the inputs could be anything that contain the right organic molecules. We already know that eating meat is environmentally unsustainable, so why not get all our protein from insects?

If eating something spat out by the same kind of 3D printers that are currently being used to make everything from jet engine parts to fine art doesn’t sound too appetizing, that’s only because you can currently afford the good stuff, says Contractor. That might not be the case once the world’s population reaches its peak size, probably sometime near the end of this century.

“I think, and many economists think, that current food systems can’t supply 12 billion people sufficiently,” says Contractor. “So we eventually have to change our perception of what we see as food.”

There will be pizza on Mars

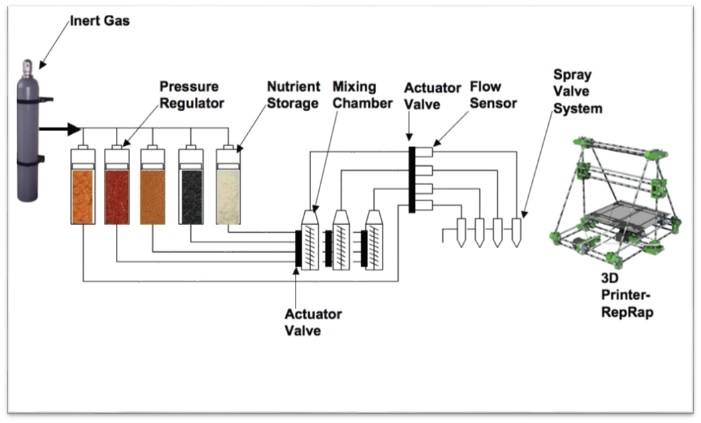

The ultimate in molecular gastronomy. (Schematic of SMRC’s 3D printer for food.)SMRC

If Contractor’s utopian-dystopian vision of the future of food ever comes to pass, it will be an argument for why space research isn’t a complete waste of money. His initial grant from NASA, under its Small Business Innovation Research program, is for a system that can print food for astronauts on very long space missions. For example, all the way to Mars.

“Long distance space travel requires 15-plus years of shelf life,” says Contractor. “The way we are working on it is, all the carbs, proteins and macro and micro nutrients are in powder form. We take moisture out, and in that form it will last maybe 30 years.”

Pizza is an obvious candidate for 3D printing because it can be printed in distinct layers, so it only requires the print head to extrude one substance at a time. Contractor’s “pizza printer” is still at the conceptual stage, and he will begin building it within two weeks. It works by first “printing” a layer of dough, which is baked at the same time it’s printed, by a heated plate at the bottom of the printer. Then it lays down a tomato base, “which is also stored in a powdered form, and then mixed with water and oil,” says Contractor.

Finally, the pizza is topped with the delicious-sounding “protein layer,” which could come from any source, including animals, milk or plants.

The prototype for Contractor’s pizza printer (captured in a video, above) which helped him earn a grant from NASA, was a simple chocolate printer. It’s not much to look at, nor is it the first of its kind, but at least it’s a proof of concept.

Replacing cookbooks with open-source recipes

SMRC’s prototype 3D food printer will be based on open-source hardware from the RepRap project.RepRap

Remember grandma’s treasure box of recipes written in pencil on yellowing note cards? In the future, we’ll all be able to trade recipes directly, as software. Each recipe will be a set of instructions that tells the printer which cartridge of powder to mix with which liquids, and at what rate and how it should be sprayed, one layer at time.

This will be possible because Contractor plans to keep the software portion of his 3D printer entirely open-source, so that anyone can look at its code, take it apart, understand it, and tweak recipes to fit. It would of course be possible for people to trade recipes even if this printer were proprietary—imagine something like an app store, but for recipes—but Contractor believes that by keeping his software open source, it will be even more likely that people will find creative uses for his hardware. His prototype 3D food printer also happens to be based on a piece of open-source hardware, the second-generation RepRap 3D printer.

“One of the major advantage of a 3D printer is that it provides personalized nutrition,” says Contractor. “If you’re male, female, someone is sick—they all have different dietary needs. If you can program your needs into a 3D printer, it can print exactly the nutrients that person requires.”

Replacing farms with sources of environmentally-appropriate calories

2032: Delicious Uncle Sam’s Meal Cubes are laser-sintered from granulated mealworms; part of this healthy breakfast.TNO Research

Contractor is agnostic about the source of the food-based powders his system uses. One vision of how 3D printing could make it possible to turn just about any food-like starting material into an edible meal was outlined by TNO Research, the think tank of TNO, a Dutch holding company that owns a number of technology firms.

In TNO’s vision of a future of 3D printed meals, “alternative ingredients” for food include:

- algae

- duckweed

- grass

- lupine seeds

- beet leafs

- insects

From astronauts to emerging markets

While Contractor and his team are initially focusing on applications for long-distance space travel, his eventual goal is to turn his system for 3D printing food into a design that can be licensed to someone who wants to turn it into a business. His company has been “quite successful in doing that in the past,” and has created both a gadget that uses microwaves to evaluate the structural integrity of aircraft panels and a kind of metal screw that coats itself with protective sealant once it’s drilled into a sheet of metal.

Since Contractor’s 3D food printer doesn’t even exist in prototype form, it’s too early to address questions of cost or the healthiness (or not) of the food it produces. But let’s hope the algae and cricket pizza turns out to be tastier than it sounds.

Related Links:

Personal comment:

It looks like cats and dogs are already eating "rapid prototyped" food --from what I see on the pictures here-- and are a step forward in the future from us! ;)

But would it be given to AdriÓ Ferran, it could start to look and taste like something!

But we could also put this in perspective with the recommendation from UN (Food & Agriculture) that humanity should eat more insects in the future, both because it needs less energy and produces less carbon dioxide to produce 1kg of insects (2kg of food produce 1 kg of insects while 20kg produce 1kg of meat...) and because they provide good and healthy nutriments. As many people still don't like to eat insects due to their aspect, turn them into powder and print them might be an interesting way.

Tuesday, December 04. 2012

The Coldscape

Via Cabinet

-----

By Nicola Twilley

More than three-quarters of the food consumed in the United States today is processed, packaged, shipped, stored, and sold under artificial refrigeration. The shiny, humming stainless steel box in your kitchen is just the tip of the iceberg, so to speak—a tiny fragment of the vast global network of temperature-controlled storage and distribution warehouses cumulatively capable of hosting uncounted billions of cubic feet of chilled flesh, fish, or fruit. Add to that an equally vast and immeasurable volume of thermally controlled space in the form of shipping containers, wine cellars, floating fish factories, international seed banks, meat-aging lockers, and livestock semen storage, and it becomes clear that the evolving architecture of coldspace is as ubiquitous as it is varied, as essential as it is overlooked.

(...)

More about it and about a "perpetual winter" on Cabinet's website.

Related Links:

Monday, November 05. 2012

Geoengineering Could Be Essential to Reducing the Risk of Climate Change

-----

Using technology to cool the planet may be the only way to deal with the greenhouse gases already in the atmosphere, argues scientist David Keith.

By Kevin Bullis

David Keith spoke at MIT Technology Review’s EmTech conference this week.

Geoengineering—using technology to purposefully change the climate—is the only option for reducing the risk of climate change from greenhouse-gas emissions in the next few decades, says David Keith, a professor of public policy and applied physics at Harvard University. And he says that if it’s done in moderation, it could be much safer than some experts have argued. In fact, says Keith, effective methods of geoengineering are so cheap and easy that just about any country could do it—for better or worse.

Keith, speaking this week at MIT Technology Review’s annual EmTech conference, says it is already too late to avoid climate changes by reducing carbon emissions alone. The carbon dioxide that’s been released into the atmosphere by burning fossil fuels is already likely to cause significant harm, such as raising temperatures enough to hurt crop yields in many places. “If you want to, say, really stop the loss of Arctic sea ice or stop heat-stress crop losses over the next few decades, geoengineering is pretty much the only thing you can do,” he says (see “Why Climate Scientists Support Geoengineering Research”).

One of the main objections to geoengineering is that the measures that might be taken to cool the planet won’t exactly offset the effects of carbon dioxide, so they could actually make things much worse—for example, by altering patterns of precipitation. Keith says recent climate models suggest that injecting sulfate particles into the upper reaches of the atmosphere might not affect precipitation nearly as much as others have warned.

“I propose that you start in about 2020, and you start very, very gradually increasing your amount of sulfate engineering so that you cut about in half the rate of warming,” he says. “Not eliminate it, but cut it about in half. Cutting it in half is a big benefit.”

One of the benefits could be increased crop production. Though some critics have worried that geoengineering would alter monsoon patterns that are key to agriculture in India, Keith says moderate geoengineering could actually boost crop productivity there by 20 percent, in part by reducing temperatures.

Keith and some of his colleagues recently hired engineers to estimate how much one approach to sulfate injection might work, and how much it might cost. It could be done at first with existing airplanes—certain business jets can fly high enough to inject the particles into the upper atmosphere. Eventually we would need new planes that can fly higher. All in all, once the procedure is scaled up it would cost about a billion dollars a year and require about 100 aircraft. That’s cheap enough for most countries to pull off on their own.

The fact that it’s easy isn’t necessarily a good thing, Keith says. There’s the potential that if one country does it, another might blame that country—rightly or wrongly—for ensuing bad weather (see “The Geoengineering Gambit”).

And there are also real concerns about the impact sulfates might have on the atmosphere (see Geoengineering May Be Necessary, Despite Its Perils). It’s known that sulfates can be involved in reactions that deplete the ozone layer. As the earth warms, water vapor levels are increasing, which could exacerbate the problem. Keith is proposing a test to discover quantitatively just what the effect of the injections could be. He would introduce small clouds of sulfate and water vapor into the stratosphere using balloons, and then carefully measure the reactions that take place.

And Keith acknowledges a concern many have had about geoengineering: that using it to offset problems from climate change will reduce the incentive to tackle the greenhouse-gas emissions at the root of the problem. Even if geoengineering is employed, reducing emissions will still be important. Sulfate injection does nothing to address the ocean acidification associated with increased levels of carbon dioxide in the atmosphere. And if emissions continue to grow, ever-increasing amounts of sulfate will be needed.

But Keith thinks the potential benefits might be worth the dangers. “We don’t know enough yet to start,” he says. “But the current balance of evidence is that doing this really would reduce risks. And for that reason, we’ve got to take it seriously. It really would be reckless not to look at something that could reduce risk like this could.”

Tuesday, June 26. 2012

Urban Probiotics

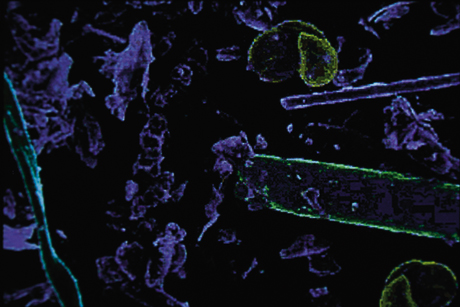

IMAGE: Gut flora redesign, using a yogurt vehicle, is already a commonplace activity at breakfast tables around the world.

For many, the consumption of probiotic supplements is already a daily routine — a regular, intentional, and frequently yogurt-based effort to re-design our intestinal flora. This makes sense: the five hundred (or so) different species of bacteria living inside our guts have an important influence on everything from our ability to digest certain foods to our emotional well-being and behaviour.

Doses of “friendly” bacteria have already been shown to cure chronic digestive illnesses, and, according to Professor John Cryan of the Alimentary Pharmabiotic Centre at University College, Cork, it’s highly likely that they will soon be used to treat “stress-related psychiatric disorders such as anxiety and depression.” These beneficial microbes are typically consumed orally, either dried and encapsulated in supplement form or cultured in a dairy base, although in extreme situations they can also be introduced directly to the colon using the somewhat horrifying-sounding technique of fecal transplant.

IMAGE: Probiotic bacteria.

Last month, however, scientists at the University of Toronto announced the results of a study that examined both babies’ gut bacteria and the bacteria present in dust samples from their homes. To their surprise, they found a significant overlap, suggesting, as Jessica Hamzelou writes in New Scientist, that babies “may be sharing their gut bacteria with the environment and vice versa.”

Extrapolating from this, public health researcher Pilar Francino goes on to speculate that “people living in the same dusty house may also share health and behavioural characteristics.”

IMAGE: A dusty house, via.

In other words, just as the colour of your walls has been shown to affect your heart rate and blood pressure, your home’s bacterial biome may be making you obese and anxious — or, of course, healthy and happy.

Forget yogurt or fecal transplants — it seems to be only a matter of time before we are able to intentionally inoculate our homes with custom blends of bacteria in order to redesign our gut flora. Designer dust will take its place alongside formaldehyde-free furniture polish and low VOC paint for the responsible homeowner.

IMAGE: A dust cloud envelopes a city, via.

Perhaps, given the rising cost of obesity-related diseases combined with the increasing occurrence of allergies, environmental bacteria supplementation will come to be seen as a public health issue, with sanitation crews spraying down pavements and gutters with a fine layer of dried lactobacilli each week.

Meanwhile, somewhere, someday, the Bazalgette of urban probiotics will install a city-wide enteric enhancement program, combining a biotic sensor network and precision bifidobacteria crop-dusting drones in order to transform the city’s streets, transit network, and shared spaces into a giant, shared digestive supplement.

Thursday, April 12. 2012

Largest Rooftop Farm by BrightFarms Coming to Brooklyn, NY

Via ArchDaily

-----

de Irina Vinnitskaya

© BrightFarms

BrightFarms CEO, Paul Lightfoot is obsessed with efficiency. Spending most of his career improving market supply chains he has now turned his attention to the market supply chains of America’s produce. BrightFarms is an innovative and straight forward program whose goal is to eliminate the wasted energy expended on travel times between the farm and the shelf, to provide more nutritious and safer produce that is grown for the table and not for the endurance of days and weeks of transport, and to create a local market where consumers know their farmers and where the food is coming from and who is responsible for growing it. Littlefoot describes the blatant problems with the food industry today – efficiently factory farming and preserving produce that moves from one and end of the country to the other and inefficiently providing nutritious and tasty produce.

The challenge is to create a model that ensures quality while keeping costs down and BrightFarms appears to have found a strategy that works: hydroponic rooftop gardening near supermarket distribution centers or local markets. The newly renam520/500 ed Federal Plaza #2, soon to be known as Liberty View Industrial Plaza to be developed by Salmar Properties, in Brooklyn, NY is set to be the world’s largest rooftop garden which will reportedly grow “1 million pounds of local produce per year, including tomatoes, lettuces and herbs”. Find out how it works after the break!

BrightFarms business model seems simple – and too good to be true. The company is essentially a middle man – connecting experienced and reliable local farmers with credited grocery stores – that finances, develops and builds the BrightFarm operation. BrightFarms ensures that both parties enter into individual agreements with the program. The grocery stores are obligated to purchase the output of the farms for a 10-year period, while farmers must guarantee the volume and quality of output. And of course the key ingredient to making this operation distinct from the trends of the country is the proximity of the farms, farmers and grocery stores. Community is essential.

Aside from providing goods that are fresher and more nutritious, BrightFarms hydroponic system also reduces carbon output drammatically. Hydroponic farming delivers nutrients to plants directly through the water without soil. These systems can be trays or columns made of PVC that expose the roots to the nutrient and mineral filled water. No soil means no land use and no heavy, gas-guzzling equipment. The water in the system can be reused, There is greater control of the nutrients which means reduced waste and the water stays in the system and can be reused which greatly reduces the agricultural runoff. It also consolidates space, which makes maintenance and harvesting much easier.

The system is perfect for urban rooftop applications, which is why Liberty View Industrial Plaza is set to be the model for urban agriculture covering the rooftop of an 8-story 1.1 million-square-foot warehouse building along Brooklyn’s Industrial Waterfront in Sunset Park. The project will provide innumerable benefits for the city. It will provide enough produce to feed 5,000 New Yorkers, will create an anticipated 1,300 permanent industrial jobs and 400 construction Jobs, and will relieve the over-burdened sewer system of 1.8 million gallons of storm water from entering the waterways. It is also a plan that is part of Mayor Bloomberg’s initiative to revitalize Brooklyn’s waterfront – which is already underway at the Brooklyn Navy Yard aka Navy Hill.

Everyone is optimistic that the project will not only bring fresh and healthy food and revitalized attitude toward local farming, but will also push the long-dormant industrial buildings into a new territory of sustainable development for cities. Follow this link to see other projects by BrightFarms.

via BrightFarms and New York Real Estate Lawyer’s Blog

Related Links:

Personal comment:

While I also definitely think that producing food closer to the place where it will be eaten is a necessary thing (but guess what? this was still the way we were producing and eating food, at least in my neighboorhood, when I was a very young kid --i.e. my grandfather was selling the excedent products of his garden to the local shop, which means: we need local shops again, as well as a different economic and consumption model--. We didn't need either to take a car to buy a few tomatoes so to say), I also question this whole idea of urban farming: how much energy does it really need to grow products? At least on rooftop and exposed platforms seems a good direction, on the contrary, to build skyscapers that need artificial lighting and air conditioning to produce food not really.

But it looks like that there will be a "competition" about the use of rooftops in the close future: will we use them to produce clean electricity (solar or by other means), locally, should we use white rooftops to reduce the global albedo index of our cities (the albedo index of soil and green plants is not good) and therefore artifically replace the solar reflexion of disappearing glaciers and ice cap, should we collect waterfrom the roofs instead, or should we use them to grow plants (and eventually capture CO2 locally too, and particles of pollution as well that we'll then eat...)?

I have the feeling that we need a more general view (systems theory?) that help take more parameters into consideration.

Maybe the solution will look like this: to bioengineer new white algae plants that we can eat, that need few enery and water to grow under a minimal amount of natural light and that help produce biocarburant... (but they will still eject C02 when you'll use that carburant... damn...)

Friday, February 17. 2012

Intermission: The Edible Balloon

Via GOOD

-----

de Julie Ma

At Chicago's Alinea restaurant, "chefs defy gravity": green apple-flavored helium-filled "balloons" have become its latest (and lightest) dessert delicacy. Diners can either pop the balloon with a pin, or devour the whole thing at once. And yes, your voice will get a few octaves higher.

Related Links:

Personal comment:

Can we think of it bigger, a breathable and/or eatable baloon like architecture?

fabric | rblg

This blog is the survey website of fabric | ch - studio for architecture, interaction and research.

We curate and reblog articles, researches, writings, exhibitions and projects that we notice and find interesting during our everyday practice and readings.

Most articles concern the intertwined fields of architecture, territory, art, interaction design, thinking and science. From time to time, we also publish documentation about our own work and research, immersed among these related resources and inspirations.

This website is used by fabric | ch as archive, references and resources. It is shared with all those interested in the same topics as we are, in the hope that they will also find valuable references and content in it.

Quicksearch

Categories

Calendar

|

|

July '25 | |||||

| Mon | Tue | Wed | Thu | Fri | Sat | Sun |

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | 31 | |||