Coming just a year after the creation of the first carbon nanotube computer chip, scientists have just built the very first actual computer with a central processor centered entirely around carbon nanotubes. Which means the future of electronics just got tinier, more efficient, and a whole lot faster.

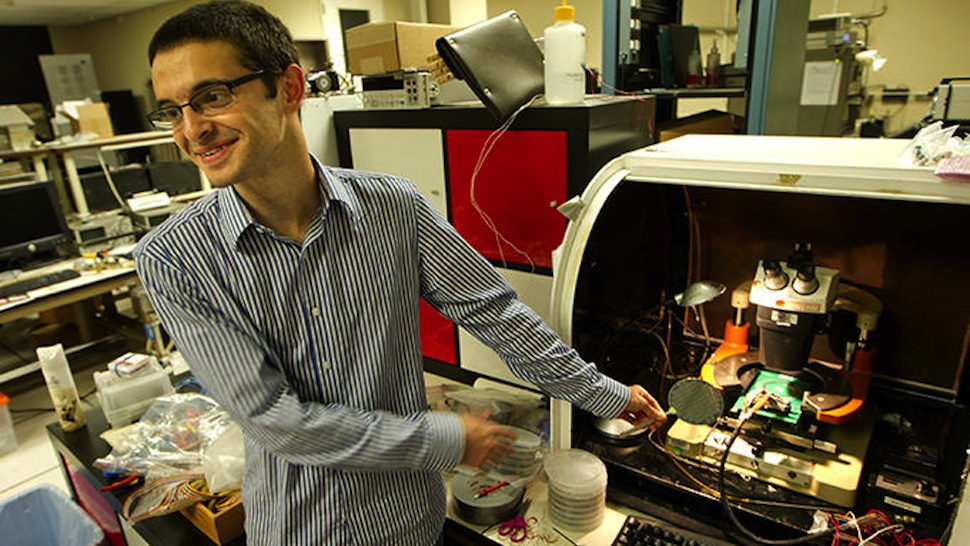

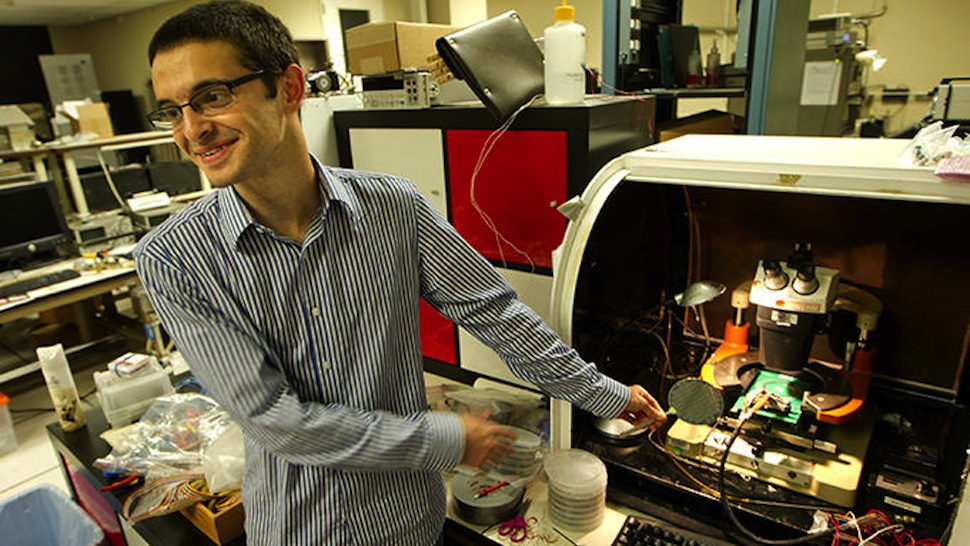

Built by a group of engineers at Stanford University, the computer itself is relatively basic compared to what we're used to today. In fact, according to Suhasish Mitra, an electrical engineer at Stanford and project co-leader, its capabilities are comparable to an Intel 4004—Intel's first microprocessor released in 1971. It can switch between basic tasks (like counting and organizing numbers) and send data back to an external memory, but that's pretty much it. Of course, the slowness is partially due to the fact the computer wasn't exactly built under the best conditions, MIT Technology Review explains:

"Don't let that fool you, though—this is just the first step. Last year, IBM proved that carbon nanotube transistors can run about three times as fast as the traditional silicon variety, and we'd already managed to arrange over 10,000 carbon nanotubes onto a single chip. They just hadn't connected them in a functioning circuit. But now that we have, the future is looking awfully bright."

Theoretically, carbon nanotube computing would be an order of magnitude faster that what we've seen thus far with any material. And since carbon nanotubes naturally dissipate heat at an incredible rate, computers made out of the stuff could hit blinding speeds without even breaking a sweat. So the speed limits we have using silicon—which doesn't do so well with heat—would be effectively obliterated.

The future of breakneck computing doesn't come without its little speedbumps, though. One of the problems with nanotubes is that they grow in a generally haphazard fashion, and some of them even come out with metallic properties, short-circuiting whatever transistor you decided to shove it in. In order to overcome these challenges, the researchers at Stanford had to use electricity to vaporize any metallic nanotubes that cropped up and formulated design algorithms that would be able to function regardless of any nanotube alignment problems. Now it's just a matter of scaling their lab-grown methods to an industrial level—easier said than done.

Still, despite the limitations at hand, this huge advancement just put another nail in silicon's ever-looming coffin.

Image: Norbert von der Groeben/Stanford