Friday, February 05. 2010

Developers think these phase-change materials could reduce the need for air-conditioning.

By Katherine Bourzac

|

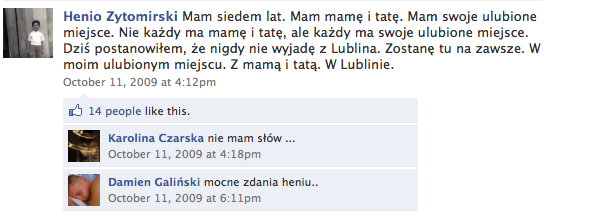

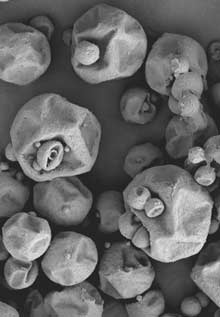

AC killers: These acrylic microcapsules are filled with a paraffin wax that can absorb heat from buildings.

Credit: Peter Schossig |

Building materials that absorb heat during the day and release it at night, eliminating the need for air-conditioning in some climates, will soon be on the market in the United States. The North Carolina company National Gypsum is testing drywall sheets--the plaster panels that make up the walls in most new buildings--containing capsules that absorb heat to passively cool a building. The capsules, made by chemical giant BASF, can be incorporated into a range of construction materials and are already found in some products in Europe.

The "phase-change" materials inside the BASF capsules keep a room cool in much the same way that ice cubes chill a drink: by absorbing heat as they melt. Each polymer capsule contains paraffin waxes that melt at around room temperature, enabling them to keep the temperature of a room constant throughout the day. The waxes work best in climates that cool down at night, allowing the materials inside the capsules to solidify and release the heat they've stored during the day.

In some southern European climates, for example, the materials absorb enough heat during the day to save 20 percent of the electricity needed for air-conditioning. In northern Europe, where nighttime temperatures are cooler, a building incorporating the materials may not need an air conditioner at all, says Peter Schossig, an engineer at the Fraunhofer Institute in Munich, Germany, whose research group worked with BASF to develop the capsules.

The work is part of a push in the construction industry toward greener building materials that help maintain comfortable temperatures without using electricity. According to the U.S. Energy Information Administration, buildings consume more than 70 percent of the electricity generated in America, and about 8 percent of that is used for air-conditioning in homes and offices. Widely used lightweight construction materials including wooden framing and drywall enable contractors to put up buildings rapidly, but they don't store much heat, so temperatures inside fluctuate throughout the day.

Phase-change materials offer a way to add thermal mass to lightweight building materials, says Leon Glicksman, professor of building technology and mechanical engineering at MIT. Since the 1950s, several companies have tried to develop passive cooling systems that take advantage of phase-change materials. But they had limited success because it's difficult to incorporate these new materials into existing building substances.

BASF makes the microcapsules by rapidly beating melted wax into hot water. Since wax and water repel one another, the wax forms small droplets. When the researchers add acrylic precursors to the mix, the repulsion between wax and water drives them to coat the droplets' surface. Finally, they add a catalyst to form an acrylic polymer shell around the wax. The resulting wet mixture can then be added to the powder that's used to make drywall or dried out and incorporated into other construction materials, including concrete and plasters.

Chemical giant DuPont also makes encapsulated phase-change materials and has incorporated them into heat-absorbing panels that it markets in Europe. BASF's strategy is a little different: the company sells the capsules to other companies to incorporate into a range of building materials, including ceiling panels, aerated concrete blocks, and drywall. Based on German electricity prices and climate conditions, a study conducted by BASF estimated that a family home made with plaster that incorporated 360 grams of the phase-change material (at a cost of $4,883) would save enough electricity to recoup the cost within five years.

National Gypsum is working with the National Renewable Energy Laboratory and California's Emerging Technologies Coordinating Council to field-test its heat-absorbing panels, which will be marketed under the name Thermalcore. The panels are made by mixing the BASF microcapsule-water solution with gypsum, the mineral used to make drywall. The paraffins used by BASF can be tailored to melt at different temperatures; those in National Gypsum's panels liquefy at 22.8 ºC (about 73 ºF). According to the company, the panels can store 22 British thermal units per square foot.

National Gypsum will take at least a year to test the panels' performance through all four seasons before bringing them to market. A spokesperson says the company may reformulate the panels to include more or less of the capsules, depending on how they perform in the climate of the western United States. Data from the field trials will also be used to model how much the panels help reduce energy consumption.

So far, the heat-absorbing capsules have only been tested in passive systems. But they could also be used in active systems in warmer climates, says MIT's Glicksman. "In commercial buildings, you could run the air conditioner at night when electricity is cheaper and use the phase-change materials to maintain lower temperatures during the day," he says. Schossig says his research group and BASF are gathering data from experimental active systems.

Copyright Technology Review 2010.

-----

Via MIT Technology Review

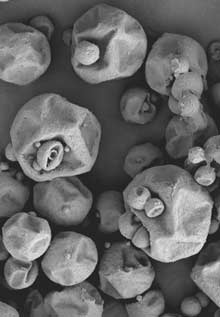

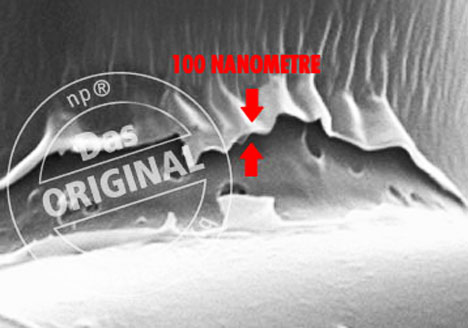

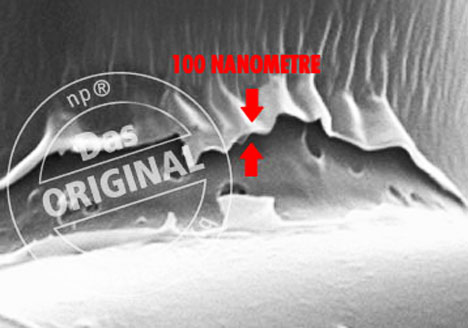

"The fissure was induced in order present an image which shows the characteristics of the coating. The image shows the SiO2 coating on a filament of a microfibre." Image: Nanopool

If it Works and is Safe, It Could Change the World

A special coating technically known as "SiO2 ultra-thin layering", but more memorably called "spray-on liquid glass", has been invented in Turkey at the Saarbrücken Institute for New Materials (the patent is owned by Nanopool). It is non-toxic promises to "protect virtually any surface against almost any damage from hazards such as water, UV radiation, dirt, heat, and bacterial infections [...] the coating is also flexible and breathable, which makes it suitable for use on an enormous array of products."

How Does it Work?

The details are still secret, but based on the information that is available, it seems like a pretty simple process. They purify silicon dioxide (SiO2, which is basically what you find in regular glass) from quartz sand, add water or ethanol molecules, and then through an unknown process are able to spray this on surfaces and get a very thin film of glass (100 nanometers, or 15-30 molecules) to stick. "The really clever part is that there are no added nano-particles, resins or additives- the coatings form and bond due to quantum forces." They also claim that it is very safe (these is already a lot of these types of inert molecules out in the wild, though I think it stills needs to be rigorously tested for toxicity).

An Almost Unbelievable List of Applications

Nanopool writes:

The flexible and breathable glass coating is approximately 100 nanometres thick (500 times thinner than a human hair), and so it is completely undetectable. It is food safe, environmentally friendly (winner of the Green Apple Award) and it can be applied to almost any surface within seconds . When coated, all surfaces become easy to clean and anti- microbially protected (Winner of the NHS Smart Solutions Award ). Houses, cars, ovens, wedding dress or any other protected surface become stain resistant and can be easily cleaned with water ; no cleaning chemicals are required. Amazingly a 30 second DIY application to a sink unit will last for a year or years, depending on how often it is used. But it does not stop there - the coatings are now also recognised as being suitable for agricultural and in-vivo application. Vines coated with SiO2 don't suffer from mildew, and coated seeds grow more rapidly without the need for anti-fungal chemicals. This will result in farmers in enjoying massively increased yields . Trials for in-vivo applications are subject to a degree of secrecy, but Neil McClelland, the UK Project Manager for Nanopool GmbH, describes the results as "stunning". "Items such as stents can be coated, and this will create anti sticking features - catheters , and sutures which are a source of infection, will also cease to be problematic."

Physorg has a few more details: "Food processing companies in Germany have already carried out trials of the spray, and found sterile surfaces that usually needed to be cleaned with strong bleach to keep them sterile needed only a hot water rinse if they were coated with liquid glass. The levels of sterility were higher for the glass-coated surfaces, and the surfaces remained sterile for months. [...] A year-long trial of the spray in a Lancashire hospital also produced "very promising" results for a range of applications including coatings for equipment, medical implants, catheters, sutures and bandages. The war graves association in the UK is investigating using the spray to treat stone monuments and grave stones, since trials have shown the coating protects against weathering and graffiti. Trials in Turkey are testing the product on monuments such as the Ataturk Mausoleum in Ankara. "

Promising, but Let's Wait and See

I'm still waiting for more tests (real-world and lab) before getting too excited. But if it works as promised, this could be a new super-material like graphene, with multiple applications in tons of different fields. And if it really makes things more durable and reduces or removes the need for strong chemicals to clean something, it could have a pretty significant positive environmental impact. But it could also have unforeseen effects, so let's not rush to put this everywhere.

Via Nanopool, Physorg

More Green Science & Technology

Making High-Tech Aircraft Parts with... Cork

Better Air Quality Means Fewer Ear Infections in Children

New Antireflective Coating Boosts Lifetime Energy Capture of Solar Cells

-----

Via TreeHugger

Virtual memorials are nothing new — people have been paying their respects to departed loved ones on Facebook and Myspace for years. But a Facebook page set up for Henio Zytomirski, a 6-year-old Polish boy who was killed during the Holocaust, is truly revolutionizing the way we recount history and remember the dead. His profile is, in essence, a virtual museum. Virtual memorials are nothing new — people have been paying their respects to departed loved ones on Facebook and Myspace for years. But a Facebook page set up for Henio Zytomirski, a 6-year-old Polish boy who was killed during the Holocaust, is truly revolutionizing the way we recount history and remember the dead. His profile is, in essence, a virtual museum.

Last summer, a group of people in Lublin, Poland, and Israel — including Henio’s cousin Neta Zytomirski Avidar — created a Facebook profile for the boy, who was sent to the Majdanek death camp in 1942. According to the AP, the idea grew out of a group called Grodzka Gate-NN Teater, which uses the arts to remember victims of the Holocaust. Henio was chosen because there were so many photos and letters available to draw from, which makes his profile a truly rich reading experience.

The profile functions as kind of a piecemeal storybook, with Polish status updates in Henio’s voice as well as photos and other updates in the third person that tell his tale. Henio’s own voice is simple and touching, as you can see in the selection below. (Rough Translation: “I am seven years old. I have a mom and dad. I have a favorite place. Not everyone has a mom and dad, but everyone has their favorite place. Today I decided that I will never leave Lublin. I will stay here forever. In my favorite place. With Mom and Dad. In Lublin.”)

According to the AP, not everyone is happy with the project — the news company cites Adam Kopciowski, a historian at Lublin’s Marie Curie-Sklodowska University who specializes in Jewish studies, who thinks that writing in the dead boy’s voice is ethically unsound and amounts to “abuse toward a child that has been dead for the past 70 years.” Others have also raised the fact that the page — much like Doppelganger Week — violates Facebook’s TOS.

Still, Henio’s cousin makes very clear in a note on the profile that the young boy’s voice is meant to be purely speculative, and that he is to function as a symbol:

“We try to reconstruct his life in the ghetto from survivors’ testimonies, from documents, from knowing the history of Lublin during the Nazi occupation. From all of these we try to guess what might have been his testimony.

Henio is also a representing figure, a symbolic figure, an icon. His figure represents the destruction of the ancient Jewish community of Lublin.

His figure brings to Facebook the story of the Jewish community under the Nazi occupation regime and of its ruin.”

And judging by his 3,000+ fans, scores of thankful wall posts and avalanche of virtual gifts, people have become enamored of the long-lost boy.

Aside from being a touching memorial to a tragically departed boy, Henio’s profile is also a fascinating use of social media as an educational tool. Some of us have probably visited the United States Holocaust Memorial Museum in Washington, D.C. Upon entering, you receive a passport depicting someone who experienced the Holocaust, and throughout your tour through the museum, you learn his or her fate. Henio’s page brings this experience to another level, allowing you to interact with the boy, and to learn about his life in a way that integrates fully into your own social media experience.

This profile only goes to show how sites like Facebook are no longer silly time wasters or places to troll for your next collegiate hookup, they provide us with news, entertainment, advertisements and, now — as more and more people are seeing it as both a news portal and source — education. I recently became a friend of Henio’s, will you?

-----

Via Mashable

To test the night vision technology in the Mercedes E-Class, Guy Bird took on the hairpins of the Stelvio Pass in the Italian Alps, in the dark. With no lights. He also made a short film of his unusual road trip...

Night vision technology has come a long way since the first heat-sensing systems used in WWII by the US Army to spot enemy targets writes Guy Bird. Today, the latest systems are now so effective and affordable they're being offered as road safety devices on civilian cars.

Car manufacturer research found that many accidents were occurring on poorly-lit country roads due to cars only using dipped beams to avoid blinding on-coming traffic. They then worked out that night vision systems in tandem with dipped beams greatly enhance drivers' ability to see further down the road and spot hazards earlier.

To see how good night vision technology has become three plucky British journalists drove up the infamous 60-hairpin Stelvio Pass in the Italian Alps in a night vision-equipped Mercedes E-Class at midnight, and then taped up the exterior lights to see if the night vision system alone might be enough to navigate by.

The car uses ‘near infrared' technology (also known as ‘active infrared') to allow the driver to ‘see' just beyond the visible light spectrum of the human eye. It works by illuminating the road with invisible, and therefore non-reflective, infrared light from the car's two inner front headlamps. A tiny infrared light-sensitive camera mounted in the windscreen then records what it sees and beams the greyscale images to a small LCD display on the dashboard.

The system in the new E-Class not only detects pedestrians, cyclists or obstacles up to 90 metres ahead, but also highlights them via a graphic on-screen framing device to help avoid them. Luckily, halfway up the Stelvio Pass at midnight pedestrians and cyclists are thin on the ground – but the technology's still useful for displaying the odd car, plus obstacles like stone walls and boulders, behind which lie huge drops down the mountainside.

Mercedes' system is not the first to be plumbed into a passenger car but most of the others major on ‘far' or ‘passive' infrared technology that processes infrared radiation and displays the images on the car's front windscreen.

While they can work up to greater distances than ‘near infrared' the images tend to be much grainier and lower resolution, and Mercedes says such heat-reliant systems don't always work as well if the object to be detected is of a similar temperature to the atmosphere around it, ie rocks or boulders warmed up by hot weather may fail to be picked up by the sensor.

To test the theory that our night vision really could substitute for headlights, the car's main and side headlamps were taped over, leaving only the tiny but crucial infrared light elements exposed. Even so, you'd be hard pressed to read a book by the light left remaining outside, let alone drive anywhere. A safety car drove several hairpins in front (to alert any cars coming the other way) and then it was the turn of our night vision car to set off.

Mercedes' system only kicks in at about 14mph, so once the night vision system has been activated by a small button in the dash it takes a real leap of faith to accelerate into the darkness and just wait for the satnav screen to start beaming back images. But put your foot down properly and the critical speed is quickly reached – a second later the camera is feeding back crystal clear, virtually real-time images to the driver's cabin.

It's a particularly unnerving experience driving a car up a narrow, unlit mountain pass navigating almost completely on the basis of images that resemble a black and white videogame on a screen normally reserved for consulting the satnav.ght vision But after some mental and physical adjustment, traversing the straighter sections gets easier and we go above 25mph.

The hairpins are trickier. The night vision images that feed back as each corner is taken are no more than a fast-moving blur of impending wall. The only way to tackle them is to pick a line hugging the outside wall before you enter the corner and make the turn into the middle of the darkness as smoothly as possible. Without being able to see inside the curve, memories of turns taken in daylight practice runs help, but as soon as the road straightens up again the night vision tech shows the path forward remarkably clearly. After ten minutes more concentration, and dozens more hairpins, the summit is reached.

Of course, ours was a slightly daft test that should ‘not to be tried at home' – or halfway up a mountain – but it nonetheless shows how sharp an image ‘near infrared' night vision can project and how effective a tool it could be for road safety. It's also quite affordable at £1,100 and could well filter down to cheaper and smaller models in time, just like so many other devices from airbags to ABS.

Guy Bird is a freelance journalist, specialising in cars and car design. This article appears in the CR February issue.

-----

Via Creative Review

Personal comment:

Just interested by the strange, unlikely (and a bit nerdly stupid) experience.

London-based Steven Chilton of Marks Barfield Architects, the designers of the London Eye, has sent us fascinating images of Villa Hush Hush, an innovative high end residence they are currently developing. The project has been privately commissioned and currently has planning permission.

Images + project description after the jump.

Villa Hush-Hush - by Steven Chilton of Marks Barfield Architects, designers of the London Eye

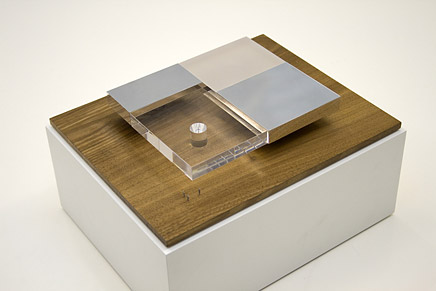

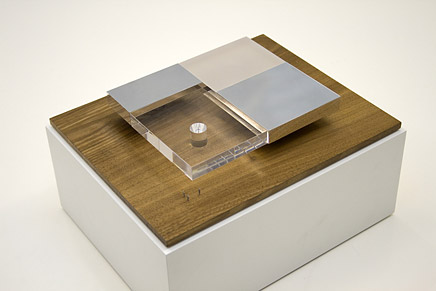

Specifically created for sensitive sites and affording sensational views, Villa Hush-Hush is designed as a spectacular new home concept that can disappear into a landscape, but at the touch of a button be lifted above the treetops to provide wonderful panoramic views.

Project Architect and designer Steven Chilton said: “The inspiration comes from a fascinating brief to create an individually crafted and beautiful home. The design derives from a simple cubic composition inspired by the work of Donald Judd. Unique in design and function, and unlike any other home in the world, it will offer a memorable, moving, living experience.”

In plan, the villa is divided into four clearly defined zones, of which it is possible to elevate two, depending on the internal arrangement and client’s requirements. The clean simplicity of the forms concentrates the relationship between the villa, the viewer and its environment.

In plan, the villa is divided into four clearly defined zones, of which it is possible to elevate two, depending on the internal arrangement and client’s requirements. The clean simplicity of the forms concentrates the relationship between the villa, the viewer and its environment.

Externally the moving element transforms the villa into a kinetic sculpture creating a unique spectacle with an assured quality. Inside, bespoke designs by interior specialists Candy & Candy will frame spectacular views that would slowly be unveiled as part of the villa rises up above the surroundings bringing the horizon into view, creating a unique, memorable, and heightened feeling.

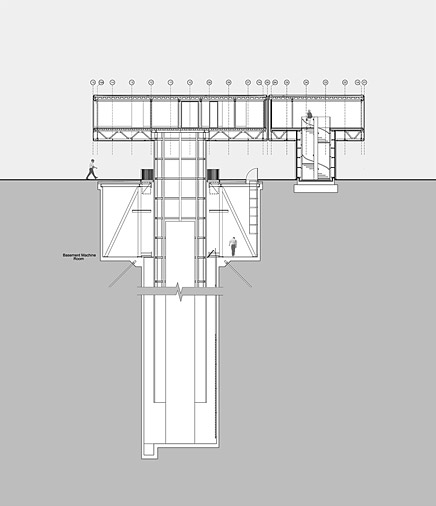

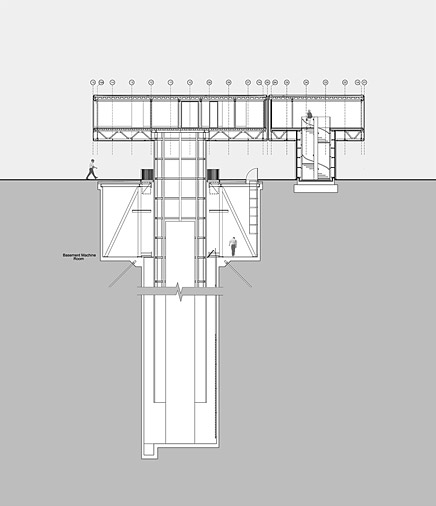

Engineers Atelier One designed the lifting mechanism which pushes a support column up out of the ground raising the moving element of the villa from its lowered position to the required height. The lifting mechanism has been designed such that the lifting, at around 10cm per second, is gentle and steady. The moving element of the villa can be lowered more quickly as it is easier to drop the structure than lift it. This means it would take about five minutes to reach its full height above ground and about three minutes to descend.

The support column and the moving element of the villa are balanced by 260 tonnes of steel plate acting as a counter-weight suspended in a cradle and guided within a central inner steel tube structure, and are driven by eight 22kW drive motors, equivalent in total to an energy efficient family sized vehicle. Redundancy is designed into the system of motors and gearboxes such that in the event of failure of a single drive unit the mechanism will function as normal, with no reduction in performance.

Working with dynamic specialists Motioneering, dampers have been designed into the structure to limit the dynamic response of the structure at various heights and wind speeds to ensure the highest levels of comfort.

To maximise the economic efficiency of the structure, the structure is restricted from being elevated during very high winds. The high wind limit for this is around Beaufort Scale 7 which is described as when whole trees are in motion and effort is needed to walk against the wind. In these cases the moving element of the villa would remain comfortably in its lowered position.

About Steven Chilton, Associate Director MBA

Born in London in 1971, Steven first made his mark on the environment as a graffiti artist prior to pursuing a career in architecture. After studying at Manchester University where he received a Distinction in design, he joined MBA in 1997 and spent the first three years working on the design and construction of the London Eye.

Since then he has designed the award winning Millbank Millennium Pier outside Tate Britain, collaborating with acclaimed conceptual artist Angela Bulloch and recently created the competition winning sculpture to mark the entry point into Wales called the Red Cloud.

-----

Via Archinect

|

Virtual memorials are nothing new — people have been paying their respects to departed loved ones on Facebook and Myspace for years. But a Facebook page set up for Henio Zytomirski, a 6-year-old Polish boy who was killed during the Holocaust, is truly revolutionizing the way we recount history and remember the dead. His

Virtual memorials are nothing new — people have been paying their respects to departed loved ones on Facebook and Myspace for years. But a Facebook page set up for Henio Zytomirski, a 6-year-old Polish boy who was killed during the Holocaust, is truly revolutionizing the way we recount history and remember the dead. His