Monday, January 17. 2011

Via Manystuff

-----

ARCHI ZINES is a showcase of international fanzines, pamphlets and journals that provide an alternative discourse to mainstream architectural publishing. Launched by Elias Redstone and Folch Studio, the project celebrates and promotes publishing as an arena for architectural commentary, criticism and research, and as a creative platform for new photography, illustration and design.

Alternative publishing has had a dynamic and important relationship with architecture over the years, with prolific moments in the 1960s, 1970s and 1990s. A recent resurgence has seen new titles emerge in countries around the world, from Argentina, Belgium and Chile to the UK and USA. ARCHI ZINES brings together this international collection of publications for the first time as an important resource for architects, designers, critics, photographers and anyone interested in discussing the buildings and spaces we inhabit.

Monday, December 13. 2010

Via ArchDaily

-----

by David Basulto

Remember Zebra’s holographic sheets we presented you back in February? Well, Zebra Imaging has released new videos that show how this technology can be used for planners/urban designers (as seen on Seattle’s video above), or to get an accurate preview of HVAC.

Price for this sheets? $1,500 for a 12- x 18-inch version to $3,500 for the largest 2- x 3-foot size.

Another video after the break:

Personal comment:

Instead of the old white plaster models...

Wednesday, March 10. 2010

Open Source Ecology

"Open Source Ecology is a movement dedicated to the collaborative development of tools for replicable, open source, modern off-grid 'resilient communities.' By using permaculture and digital fabrication together to provide for basic needs and open source methodology to allow low cost replication of the entire operation, we hope to empower anyone who desires to move beyond the struggle for survival and 'evolve to freedom.'"

-----

Via Pruned

Tuesday, February 16. 2010

by Andrew Price

How much energy we can generate with wind and solar power projects depends, of course, on the wind and the sun. So being smart about where we put solar panels and turbines will is pretty important. A company called 3TIER has made a business out of providing "prospecting tools" for renewable energy. Here's their latest map for where solar power can be harvested in the western hemisphere:

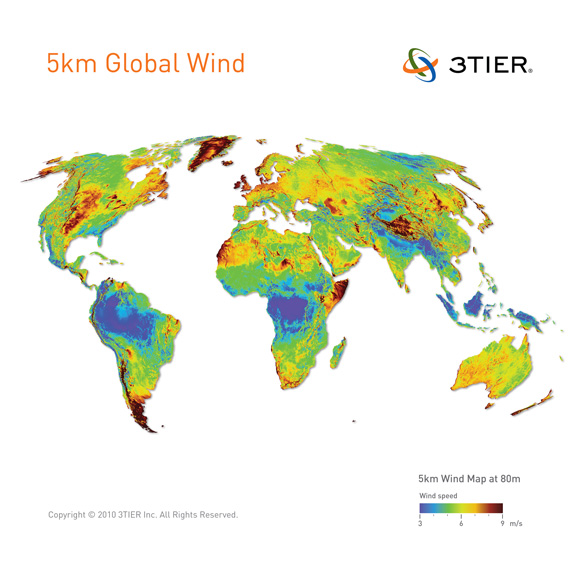

And here's their map of global wind power potential:

They go into way more detail, too. One analysis looks at how wind power varies across the United States in an El Niño year. Of course, when it comes to actually building wind and solar projects many other factors come into play. Local politics, Nimby concerns, and conflicts with wildlife are just a few. The distribution network matters too. Greenland looks great for wind power, but it'd be tough transporting that energy to big markets. But knowing where the resources are is a critical first step in the shift to clean energy and it's encouraging that there's a market for that information.

-----

Via GOOD

Friday, February 05. 2010

Developers think these phase-change materials could reduce the need for air-conditioning.

By Katherine Bourzac

|

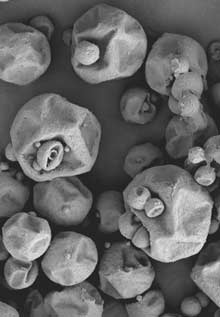

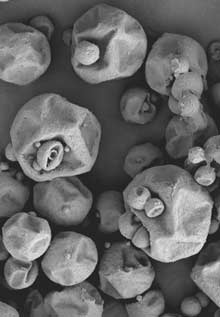

AC killers: These acrylic microcapsules are filled with a paraffin wax that can absorb heat from buildings.

Credit: Peter Schossig |

Building materials that absorb heat during the day and release it at night, eliminating the need for air-conditioning in some climates, will soon be on the market in the United States. The North Carolina company National Gypsum is testing drywall sheets--the plaster panels that make up the walls in most new buildings--containing capsules that absorb heat to passively cool a building. The capsules, made by chemical giant BASF, can be incorporated into a range of construction materials and are already found in some products in Europe.

The "phase-change" materials inside the BASF capsules keep a room cool in much the same way that ice cubes chill a drink: by absorbing heat as they melt. Each polymer capsule contains paraffin waxes that melt at around room temperature, enabling them to keep the temperature of a room constant throughout the day. The waxes work best in climates that cool down at night, allowing the materials inside the capsules to solidify and release the heat they've stored during the day.

In some southern European climates, for example, the materials absorb enough heat during the day to save 20 percent of the electricity needed for air-conditioning. In northern Europe, where nighttime temperatures are cooler, a building incorporating the materials may not need an air conditioner at all, says Peter Schossig, an engineer at the Fraunhofer Institute in Munich, Germany, whose research group worked with BASF to develop the capsules.

The work is part of a push in the construction industry toward greener building materials that help maintain comfortable temperatures without using electricity. According to the U.S. Energy Information Administration, buildings consume more than 70 percent of the electricity generated in America, and about 8 percent of that is used for air-conditioning in homes and offices. Widely used lightweight construction materials including wooden framing and drywall enable contractors to put up buildings rapidly, but they don't store much heat, so temperatures inside fluctuate throughout the day.

Phase-change materials offer a way to add thermal mass to lightweight building materials, says Leon Glicksman, professor of building technology and mechanical engineering at MIT. Since the 1950s, several companies have tried to develop passive cooling systems that take advantage of phase-change materials. But they had limited success because it's difficult to incorporate these new materials into existing building substances.

BASF makes the microcapsules by rapidly beating melted wax into hot water. Since wax and water repel one another, the wax forms small droplets. When the researchers add acrylic precursors to the mix, the repulsion between wax and water drives them to coat the droplets' surface. Finally, they add a catalyst to form an acrylic polymer shell around the wax. The resulting wet mixture can then be added to the powder that's used to make drywall or dried out and incorporated into other construction materials, including concrete and plasters.

Chemical giant DuPont also makes encapsulated phase-change materials and has incorporated them into heat-absorbing panels that it markets in Europe. BASF's strategy is a little different: the company sells the capsules to other companies to incorporate into a range of building materials, including ceiling panels, aerated concrete blocks, and drywall. Based on German electricity prices and climate conditions, a study conducted by BASF estimated that a family home made with plaster that incorporated 360 grams of the phase-change material (at a cost of $4,883) would save enough electricity to recoup the cost within five years.

National Gypsum is working with the National Renewable Energy Laboratory and California's Emerging Technologies Coordinating Council to field-test its heat-absorbing panels, which will be marketed under the name Thermalcore. The panels are made by mixing the BASF microcapsule-water solution with gypsum, the mineral used to make drywall. The paraffins used by BASF can be tailored to melt at different temperatures; those in National Gypsum's panels liquefy at 22.8 ºC (about 73 ºF). According to the company, the panels can store 22 British thermal units per square foot.

National Gypsum will take at least a year to test the panels' performance through all four seasons before bringing them to market. A spokesperson says the company may reformulate the panels to include more or less of the capsules, depending on how they perform in the climate of the western United States. Data from the field trials will also be used to model how much the panels help reduce energy consumption.

So far, the heat-absorbing capsules have only been tested in passive systems. But they could also be used in active systems in warmer climates, says MIT's Glicksman. "In commercial buildings, you could run the air conditioner at night when electricity is cheaper and use the phase-change materials to maintain lower temperatures during the day," he says. Schossig says his research group and BASF are gathering data from experimental active systems.

Copyright Technology Review 2010.

-----

Via MIT Technology Review

Monday, February 01. 2010

A new company puts silicon transistors on plastic for flexible displays.

By Kate Greene

|

Print out: This plastic material is used as the backing for Phicot's amorphous silicon electronics.

Credit: Phicot |

Engineers and technophiles have long dreamt of plastic-based displays that are flexible, lightweight, and rugged compared to their glass-backed counterparts. But plastic screens still aren't widely available, partly because they're so hard to manufacture reliably in large numbers.

Now a company called Phicot has adapted a technique for printing amorphous silicon electronics onto plastic that could finally make such displays practical. The manufacturing technique, already used to make cheap solar cells, involves depositing chemicals on long sheets of plastic as they are fed through a series of rollers. Phicot is a subsidiary of PowerFilm of Ames, IA, which already makes amorphous silicon solar cells using this roll-to-roll process.

"The basic technology of roll-to-roll can bring the price down and make plastic an excellent option for the back half of the display," says Frank Jeffrey, cofounder and CEO of PowerFilm.

Most modern displays rely on transistors made of polysilicon--a semiconductor that allows electrons to move fast enough for video. The problem with polysilicon is that it needs to be deposited at high temperatures that melt plastic. So Phicot turned to amorphous silicon, which can be deposited at low temperatures and yet is still fast enough to control the pixels of electrophoretic displays such as E-Ink, and eventually those in an organic light-emitting diode (OLED) display.

At Phicot's facility, layers of amorphous silicon and insulating materials are deposited onto plastic. These rolls of plastic are then sent to a facility at HP Labs, where engineers use a novel kind of lithography, called self-aligned imprint lithography (SAIL), to etch transistors onto the plastic's surface.

Once the transistors have been deposited, the screen itself must be added. HP has tested its transistors using E-Ink and with its own reflective display technology, capable of showing color and video. According to Carl Taussig, director of HP's information surfaces labs, the amorphous silicon transistors could, with slight changes to their chemical makeup, also drive OLEDs.

Phicot isn't the only company trying to make plastic-based displays. Polymer Vision, a spin-off of Philips, and Plastic Logic are both promising products in the near future. However, these devices will rely on transistors made of organic materials, which are easy to deposit on plastic at low temperatures, but operate more slowly than those made of amorphous silicon. While organic transistors are good enough to power electrophoretic displays, they are incompatible with OLEDs. Another company, Kovio, is aiming to print silicon on plastic using technology that resembles an ink-jet printer; the main applications at this point are RFID tags.

Another advantage of amorphous silicon over organic materials is that its electronic performance is well known. "Organics are less well developed," says John Rogers, professor of materials science at the University of Illinois, Urbana-Champaign. "[Organic components] have uncertain stability and limited long-term reliability; they also have not been used in large-scale applications."

The transition from thin-film solar to printing display transistors was relatively simple, says PowerFilm's Jeffrey. The major difference is that the layers are deposited in a different order. Some layers also need to be doped--adding impurities to change a layer's electrical properties--in a different way. "We used our solar-cell machines to do the first development work," he says. "It was very straightforward."

Phicot is planning to move to a facility in Silicon Valley by the end of the year to take HP's SAIL technology to a large space.

But the process is far from perfect. Jeffrey says that the engineers are quickly solving many of the defect challenges--the major obstacle to mass production at this point. For instance, the process must be fine-tuned so that the plastic isn't stressed in a way that could, down the line, result in defective circuitry.

Another challenge is making sure that the plastic is as defect-free as possible to start with. "Your plastic has to be smooth," says Alberto Salleo, professor of materials science and engineering at Stanford. "And as it goes through the rolls it shouldn't expand or crack."

Jeffrey says there may be ways to adapt the electronics to flaws in the plastic. "We have a possible option of designing our circuitry to tolerate those" he says.

Copyright Technology Review 2010.

-----

Via MIT Technology Review

Tuesday, January 26. 2010

Images via AMEE The Avoiding Mass Extinctions Engine, or AMEE, is an organization with an audacious goal: to track the energy footprint of everything on earth. It entails an enormous amount of work, from figuring out how to track it to actually aggregating the data. But the project is doing well, and AMEE has just launched a new tool that helps put much of the information gathered into the hands of anyone who wants to know. AMEE Explorer is a search...Read the full story on TreeHugger

-----

Via TreeHugger

Friday, December 11. 2009

FEATURE, FIBER — BY Blaine Brownell on December 11, 2009 AT 9:00 AM

Mycobond is a mycological bio-composite that can be used in a wide variety of applications. Instead of conventional manufacturing processes, Mycobond uses mycelium—which is essentially the root system of a mushroom—to transform loose aggregates into strong composites. This process can be varied by using different species of fungus and mixtures of aggregates in order to make a composite with an optimal density, strength, appearance, and performance for the specific application.

Additionally, Mycobond represents a low-embodied-energy manufacturing process as the material self assembles at room temperature and pressure in the dark. Furthermore, Mycobond upcycles resources like rice hulls, cotton burrs, and buckwheat hulls that are otherwise thrown away, transforming them into valuable products, including rigid board insulation and protective packaging buffers.

Click here for more information.

This product appears in Transmaterial 3.

-----

Via Transmaterial

Personal comment:

And can you also eat it after, if the material finally doesn't suits you? ...

Thursday, December 10. 2009

David McCandles is a London-based author, writer and designer who’s website is called Information Is Beautiful. I’ve never heard of an ‘independent visual and data journalist, but I have now, and think I like them. Tons of great information graphics and a weighty client-base to boot.

“My pet-hate is pie charts. Love pie. Hate pie-charts.”

www.informationisbeautiful.net

-----

Via It's Nice That

Personal comment:

Just a resource and a blog about well designed information design... project.

Tuesday, November 10. 2009

9 November 2009, 16:06

Categories: smt-energy-photovoltaic smt-chromism-color-change

By controlling light conditions, electrochromic smart windows can save costs for heating, air-conditioning and lighting and avoid the cost of installing and maintaining motorized light screens or blinds or curtains. A disadvantage is of course the fact that the smart windows themselves need to draw energy in order to do their job.

Now, researchers at National Cheng Kung University in Tainan, Taiwan, have developed a self-powered, fast-switching smart window that doubles as a solar cell, using sunlight to power its chromic behavior and making the case for energy savings even more compelling. By employing a patterned tungsten oxide/platinum electrochromic electrode and a dye-sensitized titanium dioxide nanoparticle photoanode, the self-powered photovoltachromic cell (PVCC) which exhibits distinct electrochromic characteristics of a fast switching rate and tunable transmittance under illumination. The novel device has both photoelectrochromic and photovoltaic characteristics.

Read More

Paper

-----

Via Nanoarchitecture

|